TECNOMAGNETE - Maxx : Magnetic lifting systems | JSR GROUP

MAxx

MaxX magnetic lifters are the ideal solution for handling any steel workpiece any steel workpiece whether rough or finished.

Their compact size and low weight maximize the crane capacity through a range of models with lifting capacities (WLL) from 125 kg to 2000 kg and specific versions for round surfaces and thin material.

MaxX lifter for every need in manufacturing

|

|

The polar geometry is designed to fit loads of all kinds perfectly with both flat and round surfaces while minimizing operating air gaps.

The TG series maximizes the magnetic performance for lifting thin sheet metal and pipes.

A design of excellence and a perfect constructive realization

|

|

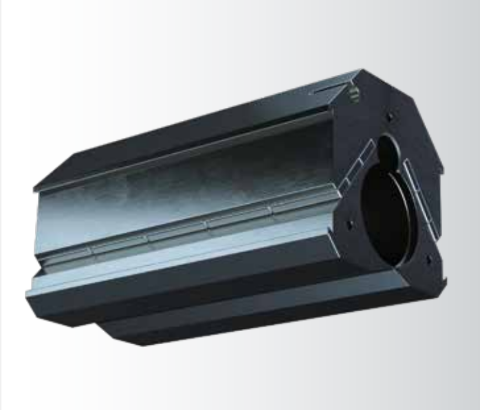

The monoblock structure of the MaxX lifter is machined with high-precision details to ensure maximum magnetic efficiency and operational reliability.

High-energy Neodymium permanent magnets are placed inside dedicated slots of the stator and inside the rotor core in order to be protected in case of shocks during use.

The magnetic rotor rotates inside the magnetic stator always maintaining the same distance over time thanks to the precision machining, the use of bearings and a unique manufacturing process that involves the magnetization of the lifter once assembled.

The final nickel-coating treatment protects the product against oxidation and the wear and tear of time.

The details make the difference

|

|

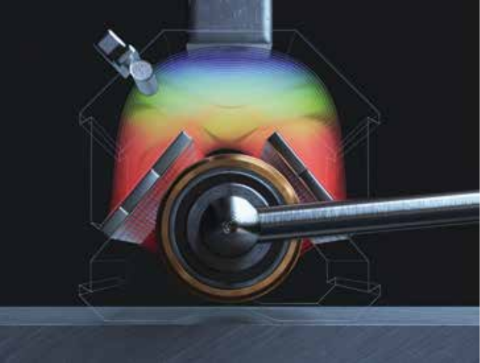

The ball bearings located at the ends of the MaxX are an integral part of the monoblock and ensure smooth rotation of the activation lever and reliability over time .

The ball bearings located at the ends of the MaxX are an integral part of the monoblock and ensure smooth rotation of the activation lever and reliability over time .

The hooking detail is designed for the firm and secure coupling with the lifting hook.

The safety catch of the lever - simple but effective - ensures optimal operation even after years of work. Its position clearly shows the operator when the lever is placed in safety mode once the hoist is activated.

The performance plates located on both sides are laser engraved on aluminum supports for durability.They clearly indicate performance on flat and round surfaces under operating conditions as a function of the quality of the contact (air gap). Each lifter displays its own serial number, the month and year of manufacture.

The polar “V” geometry to suit flat and round surfaces.

The Quality Control and testing are performed on all lifters MaxX during the various stages of production at our plant in Lainate Italy to guarantee the correct performance operation.

Double magnetic generator

|

|

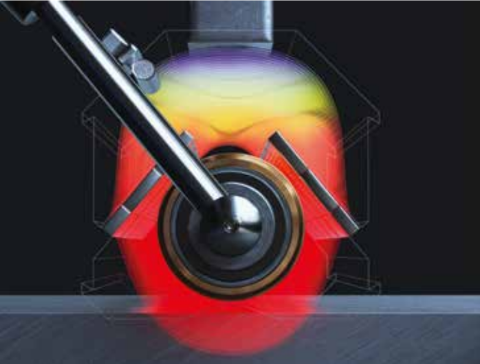

The flux generated by the high-energy permanent magnets placed in the stator slots is added to those inside the rotor for a double magnetic force extremely powerful to lift any type of workpiece in complete safety.

Rotating the lever to the rest position draws the entire magnetic flux inside the MaxX lifter, leaving the workpiece demagnetized without any residual.In addition, the perfect balance of the magnetic fields North/South inside the lifter prevents uncontrolled outflow of flux from the lifter body.

A “Smart Lever” at your service for safe magnetization

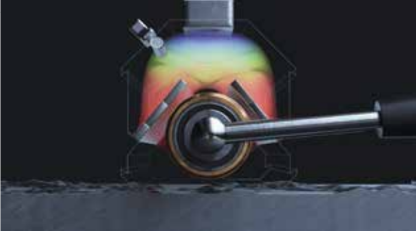

The path and intensity of the magnetic flux to clamp the workpiece to be lifted comes from a precise study on the angle of the stator magnets with that of the rotor.

The result is the “smart” behavior of the lever which informs the operator immediately through its soft or hard rotation whether the application is safe or risky due to unsuitable operating conditions such as a high air gap, too little thickness, a partial coverage of the magnetic poles or a material that is poorly permeable to magnetism.

|

|

If the operating conditions are unsafe, the lever will not allow the activation of the magnetic force